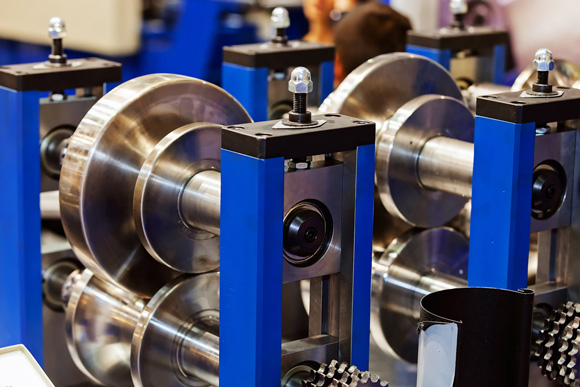

Ningbo Yeeze Commodities Co., Ltd is located in Ningbo city, the famous mold base of China. With the advantages of the mold industry, Yeeze can get a professional and excellent mold for die-casting and plastic accessories, which are two main and important parts of the umbrella, for example, the internal parts of the crank, zinc tilt of the market umbrella, which often determine the quality of the entire umbrella, as mold quality will not only affect the strength of the die-casting parts and plastic parts, but also effect the precision. Thus with good quality of die-casting parts and plastic parts, we can provide precise, steady, durable and cost-effective products for all our customers.

Yeeze is also close to Tangxi town, the famous “hardware town” of the industry. The hardware of the umbrella also takes an important role, especially we use all stainless steel hardware. We have many choices in this “Hardware Town” with good price and good quality. That’s why we can offer 100% rust-resistant umbrellas.

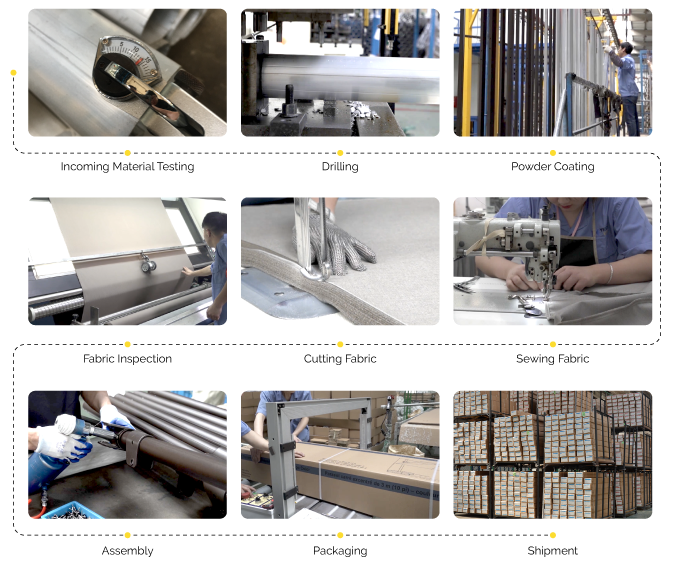

Quality control of the materials one step ahead of the purchasing is meaningful for us. However, we won’t only rely on this. We build up our own quality control system.

QUALITY MANAGEMENT _________

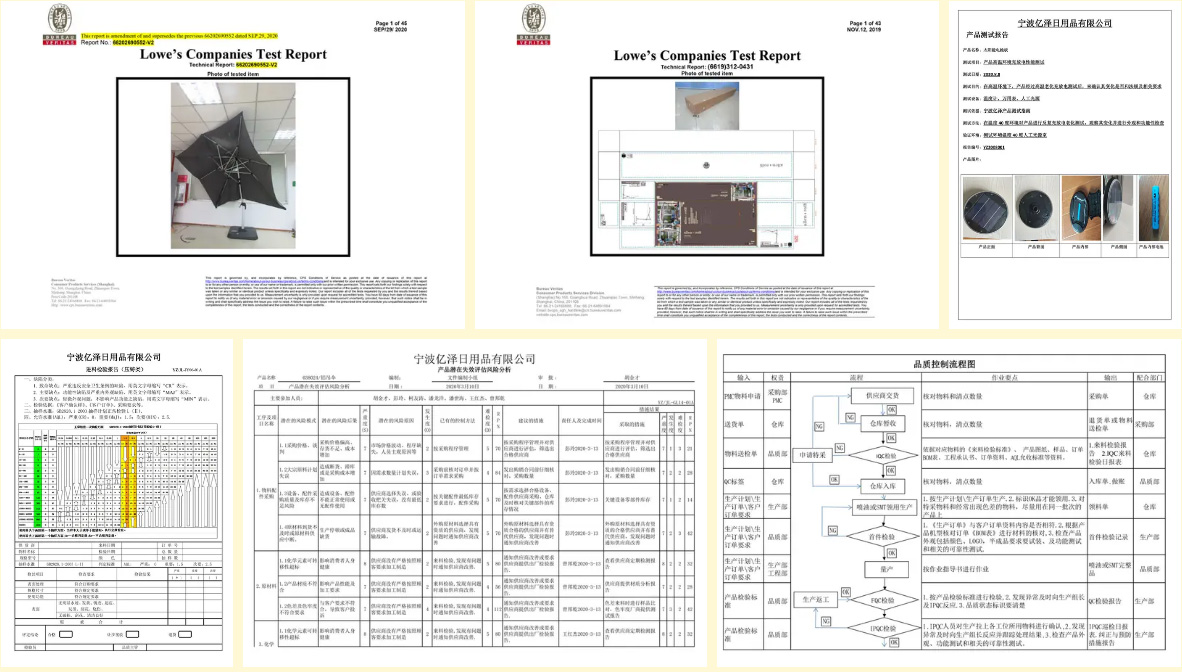

Quality control system of Yeeze guarantees the products we manufacture and deliver to our customers are of the highest and meet or exceed their intended expectations in the field. We maintain ISO-certified quality management system for the design and production of our umbrellas. We use various advanced checking equipment and procedures to inspect before and during manufacture. First article inspections are performed to verify part features prior to full production. Our quality team is em-powdering all of our workers to study and implement our quality system in order to ensure all production processes under quality controlled.

Our philosophy is that good quality based on a positive attitude. We encourage our workers to take their professional responsibilities seriously and to earn customer satisfaction with our high-quality level.

At Yeeze, quality is not only a watchword, but also a formalized system. Through strict documentation and procedures, our quality process is running through the whole process, from product review before selling, to after-sales. Our quality team applies their specialized expertise of quality control on each step, including raw material incoming checking, on-line checking and finished goods random inspection. They ensure our products are adequately reviewed and consult with customers for all of details requirements. Our quality inspection process and inspection activities include:

Product review before selling

Contract and purchase order review

Design for Manufacturing technical review

Incoming raw materials inspection

Sealed sample and first article inspection for each production steps

Production on-line checking and random inspection

Comply with relative testing certifications according to customer’s requirementw

Final inspection and testing reports and certifications per customer specification

Finished goods inspection for packing and shipping.

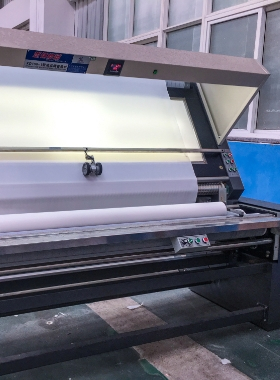

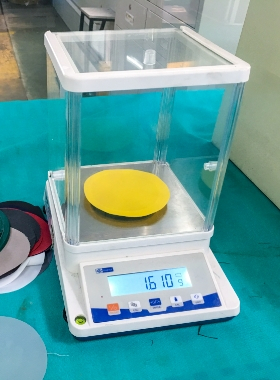

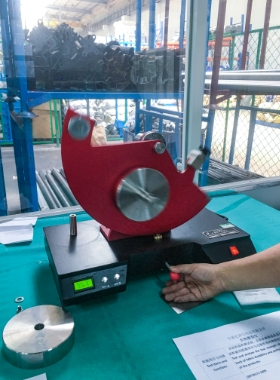

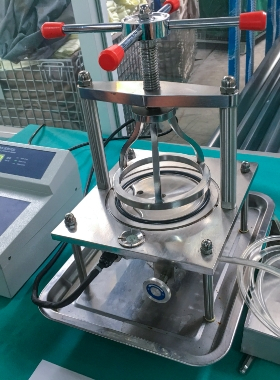

We deeply understand the importance of customer requirements for exact tolerance and precision processing quality for every part of the umbrella. So we invest and built up our own lab with big and small machines for different kinds of tests, for example, fabric running machine for defect checking, salt-spraying test for stainless steel screws, side strength and pressure test for carton box. For fabric, we do humidity test, water pressure test, and tearing test besides the color and basic weight checking. Our R&D and quality control team not only use our own equipment and tools, but also cooperate with well-know professional testing companies to meet special testing needs of our customers, for example, the wind testing for the strength of the whole umbrella.

Tube Thickness Measurer

Hardness Tester

Salt Spray Machine

Fabric Inspection Machine

Standard Light Source

Fabric Weight Test

Fabric Tearing Strength Test

Fabric Pressure Test

Carton Edge Pressure Test

Carton Pressure Test